Content index

ToggleFrom the assembly line to the automation line.

Perceptually, from an industrial perspective, they may seem like definitions of the same process but in reality this is absolutely not the case.

Let's clarify things a little.

By automation line we mean first of all a set of intelligent systems which, digitally interconnected, are able to operate autonomously in industrial production contexts.

Robotic lines are therefore the fulcrum of Industrial Revolution which leads companies within the production logic of the so-called Industry 4.0, the aim of which is to increase the efficiency of production processes together with an increase in safety at the workplace.

How a robotic line is made

To make up a robotic automation line there are, forgive the repetition, robotic elements which, in addition to guaranteeing reliability And precision, they make the flexibility their strong point.

The fundamental elements of a robotic line can be reduced to three: the control system; the systems that need to be checked; the necessary peripheral systems.

To these, however, we must add the field buses necessary for the interconnection between the robotic elements present in the line and these with the control unit.

Although it is the so-called actuators that apply the commands on the robotized line, there are two different groups of fundamental sensors that are responsible for directly collecting and providing control data.

The correct functioning of the line is therefore guaranteed by sensors with two different tasks: the first measure internal variables of the robot such as the speed of movement of some of its parts or, more simply, the battery charge level; the latter instead deal with external variables such as the storage and processing of spatial data including the paths to be taken, the distance from obstacles and the spatial coordinates of the objects with which the robot interacts in the work assigned to it.

Flexibility, a great advantage of robots, is therefore given by their character not static.

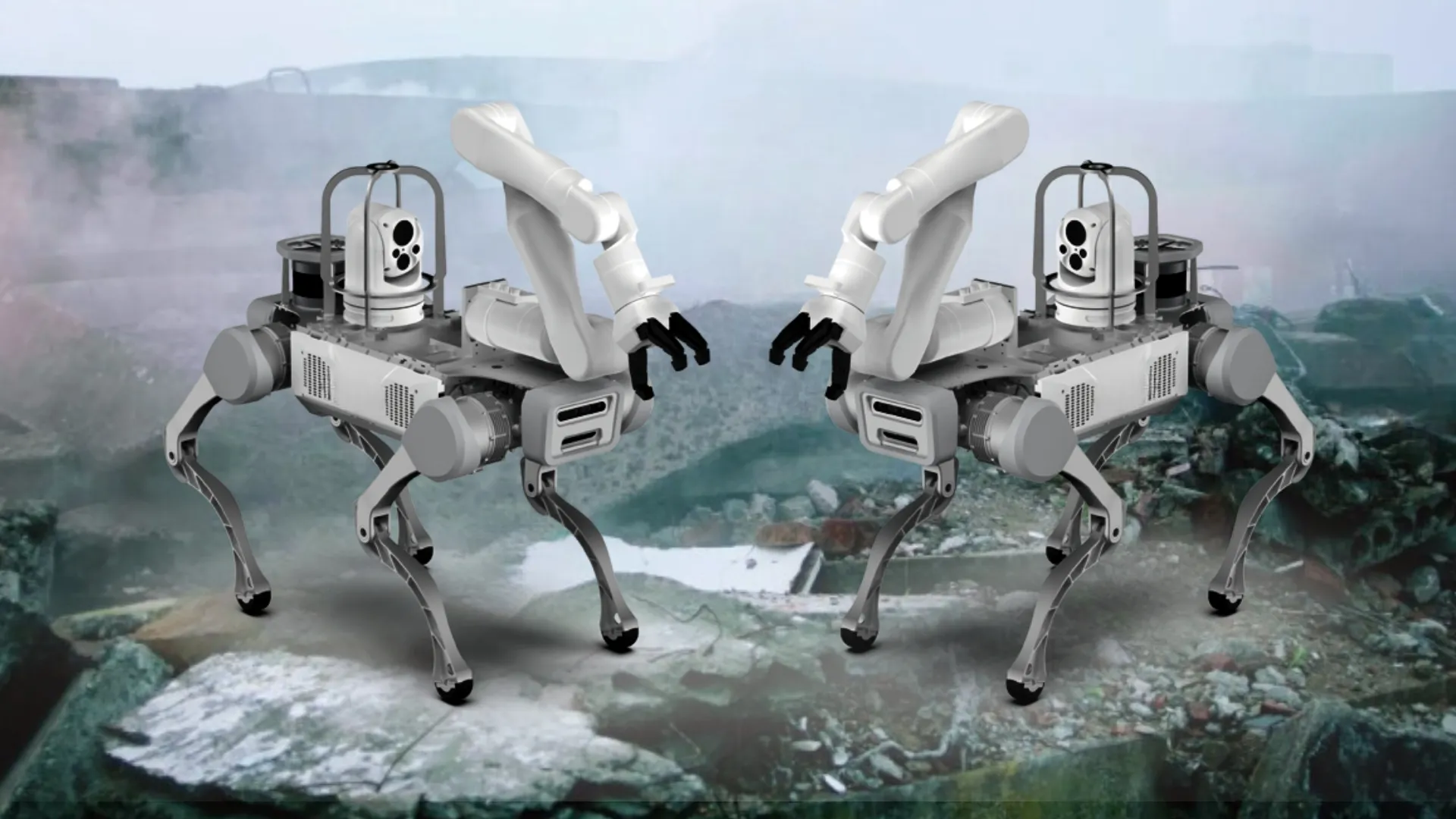

From this point of view it is essential to point out how robotic automation lines can be composed of the so-called Cobots (Collaborative Robots), which exploit the programming logic of collaborative robotics, capable of perfectly reconciling the work of machines with that of human operators in a relationship that can be of a complementary nature.

Advantages of the robotic line

The main advantage of robotic automation lines lies first and foremost in the ability to enhance and speed up industrial and warehouse processes. Added to this is the relief role that robots can carry out in relation to some jobs that would otherwise have to be carried out by human operators.

The operations carried out by the robots that make up the line are therefore maximize in times and costs, producing a clear leap forward in the efficiency of the companies that use it and indispensable production advantages.

In the case of using Cobots, the collaboration between robots and human operators involves a great deal simplification of some industrial processes becoming extremely faster and more efficient.

Thanks to line automation projects that can involve dozens and dozens of consecutive working hours, the robotic solution for industrial automation can also allow entire night or holiday shifts to be covered, without any human intervention being necessary.

Automated robotic lines, again, reduce, if not they completely eliminate the risk of errors during the production processes.

Control, communication, adjustments and measurements are in fact all activities that can be automated and therefore performed bypassing any possibility of error.

An automation line then offers various advantages, guaranteeing, for example, the real-time quality control.

Robotic lines, in addition to the advantages already listed, can boast a fundamental characteristic which is that of a high degree of customization.

They can therefore be made not only to measure, but also developed by studying the best solution to satisfy the design and production needs of each company and for each application sector.

Always in anticipation of a increasingly massive use of Cobots, the robotic lines that use it can also count on further and enormous advantages.

Cobots can be indeed reschedule quickly and without specific structural modifications, always maintaining maximum effectiveness.

The strong points of the automation lines include, regardless of the tasks for which they are intended, a very high degree of reliability and precision.

Furthermore, and this is no small thing, a robotic line will prove to be a capable investment pay for itself in time. Although an initial outlay is in fact required which cannot be considered minimal, and therefore an important investment on the part of the company, from the latter it is possible to obtain a very rapid payback which, in some cases, can amortise the expense in just one year or even less.

This is possible first and foremost thanks to accurate industrial automation design, capable of maximizing the results of the robotic line, immediately increasing savings in economic terms.

In the case of Cobots, however, in terms of economic savings it must be taken into account that there is no need to provide a environmental enrichment of large proportions.

Furthermore, benefiting from the advantages of a robotic line is the safety at the workplace. The robots, thanks to specific sensors and the possibility of being programmed to carry out certain actions, if specific events occur, are in fact able to recognize their action space and react promptly if humans, or any other obstacle, were to get closer or come between it and the destination of its movement, whether it is just the robotic arm or its entire structure, in the case of collaborative robots.

The employment impact

An automation line, and the robots that compose it, they don't steal man's work but simplify it.

Although it may be easy to fall into the trap and think that robots can completely replace the work of human operators, it must in fact be taken into account that robotic solutions are always interconnected with operators and, in turn, with the products and systems, through the communication system.

In the case of Cobots, again, the concept is clearer given that their greatest strength is precisely that of being able collaborate with humans, creating a symbiotic system, efficient, and effective for every industrial need.